Ⅰ. Description/Applications

As pure Antimony powder has been baned from China Export, we have invented a formulation with reducing ATO concentration while keeping the same flame resistant ability in a mixture powder form.

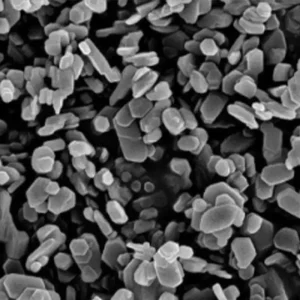

The product is able to reduce costs comparing with pure ATO, and completely solving the problems of antimony trioxide dust pollution, uneven dispersion and loss. The core is to granulate the modified dispersed powder through granulation technology, so that the masterbatch is quickly dispersed in the polymer matrix with a specific structure. The microstructure and mechanical properties of the masterbatch are stable, and the processing and fluid performance are good to meet the needs of industrial production.

Ⅱ.How to process

Since PVC cable is processed by extrusion, with a high-mixing temperature of 130 ℃ and a total duration of about 8–10 minutes, it is recommended to add the antimony masterbatch at the final stage. This ensures better performance, because the antimony masterbatch tends to settle; if it is added too early, it may sink to the bottom and negatively affect dispersion.

This masterbatch cannot be used together with a flame retardant synergist; otherwise, the flame-retardant effect will be lost.

Ⅲ.Specification

| Product code: | SHUN -201 | ||

| Testing Items | Testing standards | Metric Requirements | Testing Result |

| Melting index(160℃ , 10kg)

MFI(160℃ , 10kg) |

ISO 1133 |

≤1.2g/min |

0.85g/10min |

| Volatiles | SARTORIUS | ≤0.05% | 0.01% |

| Effective substance content | – | ≥85% | Applied |

| Granule size | – | 1.4-2g/100 | 1.81g/100 |

| Density | GB/T 21782.3-2008 | 1.83-1.88/cm3 | 1.86/cm3 |

| Bulk density | GB/T 6286-2021 | 1.2-1.4/cm3 | 1.29/cm3 |

| PVC cable testing | ||

| Formulation 1 | Formulation 2 | |

| PVC | 100 | 100 |

| DOTP | 46 | 46 |

| Calcium Carbonate | 40 | 40 |

| Calcium-Zinc stabilizer | 4 | 4 |

| Black colour masterbatch | 2 | 2 |

| Sb2O3 | 5 | |

| SHUN-201 | 5 | |

| LOI result | 31.3 | 31.2 |