I.Description/Applications

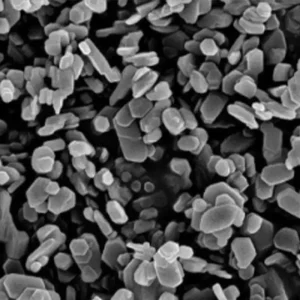

Magnesia hydroxide is made of brucite as raw material, which can be used as magnesium hydroxide flame retardant after grinding and surface modification. MH series products of our company are special functional composite surface treatment of mineral process magnesium hydroxide, used as mineral fillers for the production of halogen-free thermoplastic and heat-resistant compounds, which can obtain flame retardant properties and achieve low smoke emissions, but also reduce the toxicity of gas emitted during combustion.

| Item | ZS-3812 | ZS-1124 | ZS-381 | ZS-385 |

| Content before coating modification (%) | ≥88 | ≥88 | ≥60 | ≥88 |

| Cl- | ≤0.05 | ≤0.05 | ≤0.2 | ≤0.05 |

| Whiteness | ≥90 | ≥90 | ≥90 | ≥85 |

| Particle size D50 (μm) |

2.5-3.5 |

2.5-3.5 | 2.5-3.5 | 2.5-3.5 |

| Bulk density(g/ml) | 0.35 | 0.35 | 0.35 | 0.35 |

| Modification | Stearic acid

|

Silane | Stearic acid | Silane |

II.Specification

| EVA/PE Substrate formulation ratio | Basic formula | ZS-3812 | ZS-1124 | ZS-381 | ZS-385 | |

| EVA | 24.9 | Elongation at break(%) | 174.82 | 150.20 | 164.01 | 140.20 |

| PE | 8.31 | Tensile strength (Mpa) | 9.85 | 11.91 | 9.77 | 13.15 |

| Compatilizer | 6.66 | Melt index(g/10min) | 2.5 | 1.8 | 1.9 | 1.7 |

| Mg(OH)2 | 58.2 | Oxygen index(LOI) | 36 | 39 | 36 | 39 |

| Silicone masterbatch | 1.00 | Features | High elongation at break | High oxygen index | No discoloration during processing | High tensile strength |

- The performance indicators of different types of products are as follows (different formulations havedifferent data, for reference only)